| Accessories |Foam mills

End Mills

We supply carbide mills in diameters from 3 up to 10 mm.

Our carbide end mills have been designed for burr-free high-speed cutting up to 60,000 rpm and are available with one to 6 flutes and flute diameters from 0.1 to 20 mm.

An efficient and economical machining of Aluminium, Plastics as well as CRP and GRP materials is guaranteed with our carbide end mills.

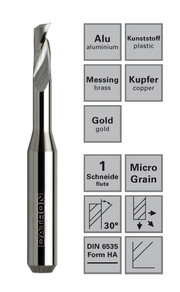

Single Flute End Mill

This specially-cut end mill is designed for very fast feed rates and very high chip removal capacity.

- Micrograin solid carbide end mill

- with single flute and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

Single Flute End Mill, with Toric Cut

With this specially ground milling cutter, you can perform particularly deep milling work with high feed rates in the material. The large chip groove allows optimal chip removal.

- Micrograin solid carbide end mill

- with single flute and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

- toric cut

Single Flute End Mill, specially balanced

This specially balanced end mill is designed for very fast feed rates and has a very high chip removal capacity.

- Micrograin solid carbide end mill

- with single flute and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA^

- specially balanced

- toric cut

Single Flute End Mill, specially balanced

This specially balanced end mill is designed for very fast feed rates and has a very high chip removal capacity.

- Micrograin solid carbide end mill

- with single flute and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA^

- specially balanced

- toric cut

Single Flute End Mill,

left hand spiral, right hand cutting

Due to the left hand spiral, the cutting pressure during milling is exerted downward, preventing especially delicate work pieces from being lifted.

- Micrograin solid carbide end mill

- with single flute and flat bottom

- 30° left hand spiral

- shank without clamping surface DIN 6535-HA

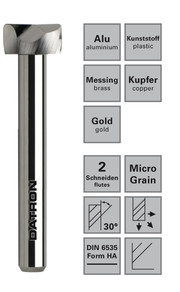

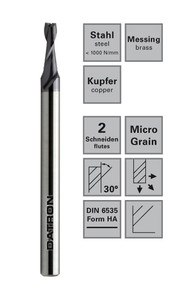

Double Flute End Mill

Compared to tools of a standard flute length, the tools with a specially short flute (Article Nos. with “K”) are much more robust and have a longer tool life.

- Micrograin solid carbide end mill

- with double flute and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

Double Flute End Mill

with Edge Radius

This tool has an edge radius, which increases the tool life. Models with toric cut have a large useable depth.

- Micrograin solid carbide end mill

- with double flute and flat bottom

- edge radius

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

Double Flute End Mill, Stepped

With stepped double flute end mills, the cutting edge diameter is considerably larger than the shaft diameter. This tool is ideally suited for milling over. With high feed rates and low infeed, large surfaces can be milled over in a short time. Due to the sharp-edged corners,

it is also possible to perform contour machining.

- Micrograin solid carbide end mill

- with two flutes and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

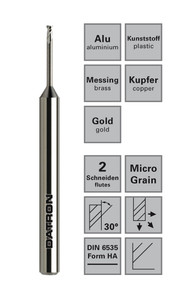

Double Flute End Mill with Toric Cut

The shank toric cut permits deeper machining.

- Micrograin solid carbide end mill

- with two flutes and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

- toric cut

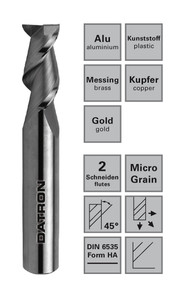

Double Flute End Mill, Contour Milling

Thanks to the 45° upcut spiral these tools are specially suited for the machining of contours.

- Micrograin solid carbide end mill

- with two flutes and flat bottom

- 45° upcut spiral

- shank without clamping surface DIN 6535-HA

Double Flute End Mill HSC+

The special feature of this mill is the steep upcutangle. The chips are removed very quickly from thework piece. In many cases this results in extremelyhigh feed rates.

- Micrograin solid carbide end mill

- with two flutes and flat bottom

- 15° upcut spiral

- shank without clamping surface DIN 6535-HA

Double Flute End Mill for Steel Machining

The cutting geometry of these micro tools is designed for steel machining. In combination with the standard X.CEED coating, these tools have a high tool life and provide excellent surface quality.

- Micrograin solid carbide end mill

- with two flutes and flat bottom

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA

Triple Flute End Mill

This SC end mill has a very short flute length and a special coating, which results in a very long tool life.

- Micrograin solid carbide end mill

- with three flutes

- 30° upcut spiral

- shank without clamping surface DIN 6535-HA centre cut

- centre cut

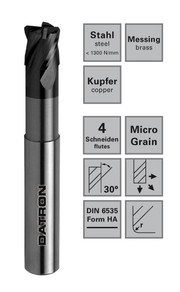

Four Flute End Mill, short version

This SC end mill has a very short flute length and a special coating, which results in a very long tool life.

- Micrograin solid carbide end mill

- with four flutes

- 30° upcut spiral

- shank with clamping surface DIN 6535-HA centre cut

- centre cut

Four Flute End Mill, long version

Thanks to the long flute length thick materials can be very well machined. As a standard, these tools are supplied with a X.CEED coating.

- Micrograin solid carbide end mill

- with four flutes

- 30° upcut spiral

- shank with clamping surface DIN 6535-HA centre cut

- centre cut with two long front side flutes

Four Flute End Mill, with Edge Radius

The special characteristics of this end mill are the rounded edges and the standard toric cut. These tools have a special X.CEED coating.

- Micrograin solid carbide end mill

- with four flutes

- 30° upcut spiral

- edge radius

- shank with clamping surface DIN 6535-HA centre cut

- centre cut

- toric cut

Four Flute End Mill

This SC end mill has a very short flute length and a special coating, which results in a very long tool life.

- Micrograin solid carbide end mill

- with four flutes

- 52° upcut spiral

- special chip space cavities

- radial under cut

- shank with clamping surface DIN 6535-HB

- centre cut

Six Flute End Mill

This end mill has a very short flute length and a special coating, which results in a very long tool life.

- Micrograin solid carbide end mill

- with six flutes

- 50° upcut spiral

- radial under cut

- shank without clamping surface DIN 6535-HA

- without centre cut

- partly with edge radius