Samples

|

|

|

|

|

|

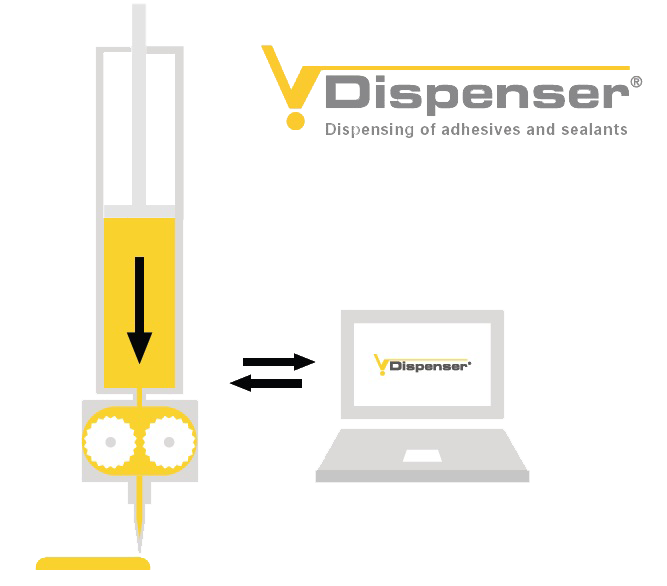

Dispensing TechnologyPump Technology VDispenserDATRON’s VDispenser was especially developed for industrial adhesive, sealing or EMC applications and convinces by its high efficiency and volume constancy. The systems work independently of pressure and viscosity, so that a readjustment of process parameters due to changes in production conditions is unnecessary. |

|

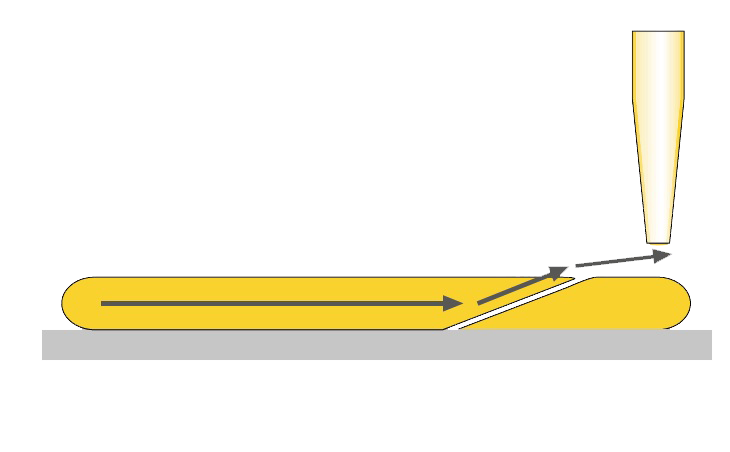

Transitions & docking points■ Clean start/stop points due to ramp-shaped transition |

|

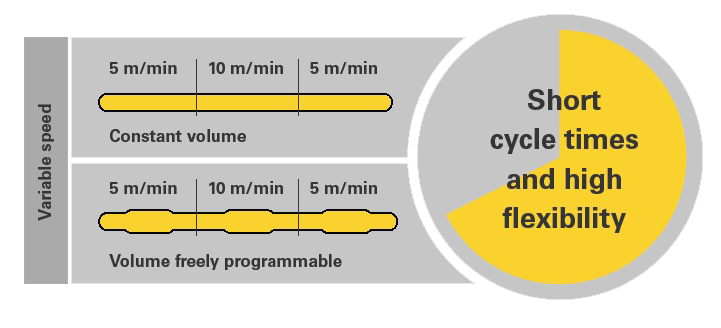

Speed & volume independent■ Short cycle times due to the possibility of acceleration and deceleration |

|

Temperature and viscosity-independent: regardless of varying production conditions■ Consistent dispensing volumes, even at different temperatures |

|

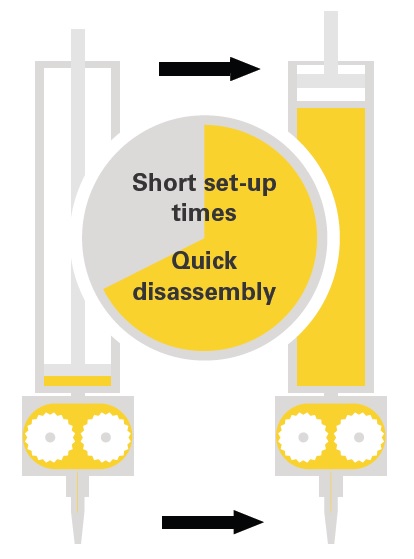

Extremely easy handling & short set-up times■ Changing of pump and gears within a few minutes |

|

Dispensing

APPLICATIONS

- Hotmelts (hot-melt adhesives) - used in automotive manufacturing, electrical engineering, furniture manufacturing and the textile industry.

- Grouting - resin systems used for casting, encapsulating or embedding electronic components.Used in electrical engineering and electronics, mechanical engineering, mold making and the cable industry. Form in Place (FIP)

- Sealing - liquid seal used instead of gaskets for plastic and metal housings and assemblies for electronics, automotive, telecommunication and consumer or household goods.

- Bonding - automated gluing used in all industrial sectors - automobile, aerospace, shipbuilding, food, medical, hygiene and electronics.

MATERIALS

Silicone, polyamides, polyurethane or polvoefine (reactive or non-reactive), oven- and room-temperature hardening epoxy-resin systems, polybutadiene, MS polymers (MS=modified silane), POP hybrid polymers, 1-component sealants, adhesives, casting material, EMC shields, hotmelts and abrasive materials.

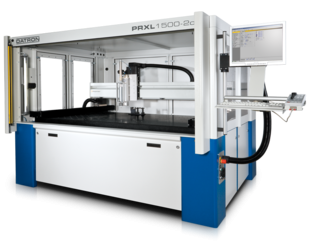

Machines

PR 500  |

PR 400  |

IR 0300  |

PRXL |

||

Dispensing Heads  |

Accessories  |

Applications  |