DATRON Foam mills

The perfect alternative to conventional PU foam machining

DATRON foam mills offer a cost-effective, time-saving and especially a rework-free alternative to conventional machining methods such as wire, water jet and laser cutting of polyurethane foams. The new DATRON foam mill series with the especially developed DATRON shank mills and countersinks models achieve uniquely precise results when milling PU foams.

Thus, bevels, contours and complex surface geometries can be achieved in a single operation:

in the shortest time and the most absolute cost-effectiveness.

-

Benefits of DATRON foam mills:

- * Time and cost saving

- * High precision in machining almost all PU foams (PE, PUR, etc.)

- * No reworking of the visible surfaces

- * Ideal for small and medium-sized batches

Advantages over wire, water jet and laser cutting:

- * Rework-free chamfers

- * Full flexibility in processing different-sized workpieces

- * Reduction of the cost of parts

Production of top quality surfaces and chamfers

Fast, accurate milling of PU foams without reworking with DATRON’S new special tools.

- 1) Face milling: Absolutely clean removal of porous materials

- 2) Outer contour milling: Edges are reproduced without need for reworking

- 3) Inner contour milling: Perfect, burr-free cutting performance with PU

- 4) Chamfer milling: DATRON special countersink achieves ideal chamfers: unsurpassed processing quality

|

|

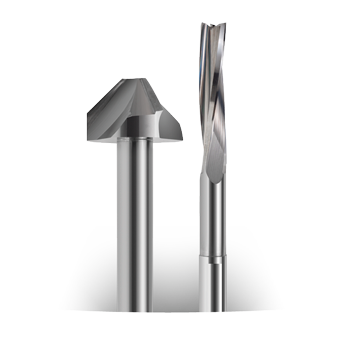

Precise cutting capacity - perfect chamfer

The new foam mills, besides having finely polished cutters also feature chip channels adjusted for PU foam machining.

In addition, DATRON especially perfected the special blade geometries and helix angles of the foam tool series.

DATRON Foam Mill

- * Micrograin solid carbide end mill

- * with three flutes and flat bottom

- * 30° upcut spiral

- * shank without clamping surface DIN 6535-HA

|

|

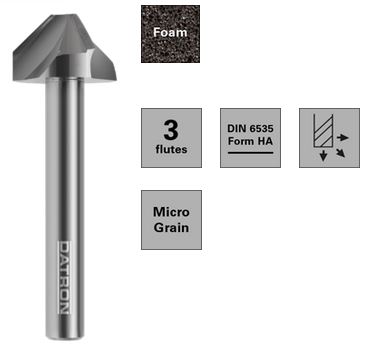

DATRON Countersink

- * Micrograin solid carbide countersink tool

- * with three flutes

- * shank without clamping surface DIN 6535-HA

|

|