DATRON PerfectCut

Fast, precise and contour accurate HSC milling for excellent surface quality.

To achieve ideal reproductions of most complex geometries in HSC milling, DATRON has invented the surface smoothing package PerfectCut. With PerfectCut your DATRON M10 Pro, M8Cube and C5 achieve utmost performance levels and machine perfect surfaces and contours without the need for post-processing – enhancing your productivity!

|

Production increases You achieve high-quality milling results faster

|

|

Better surface quality in a shorter time Achievement of better surface finish of workpieces within the same or shorter production time

|

|

Your lead particularly in micromachining You can mill even the smallest free-form surfaces and complex geometries and get perfect results

|

|

Perfect results, faster Your productivity is taken to new heights

|

|

Your machine is protected Your machine stays “fit” longer, even at high-volume production

|

DATRON CNCv9

Milling-, Drilling- and Engraving programme

The Best is the Enemy of the Good

Unfortunately this saying also applies to software development. However, you can be sure that DATRON will always be a step ahead in this respect, only offering such updates and new versions with user benefits for which we put our hands into the fire..

This is also the case with the V9 CNC machine software. It offers higher performance than the previous version, simultaneously simplifying handling for the operator. It also provides many additional options. This is achieved by additional CAD interfaces for accessing already existing data and the simplification of commands.

DATRON works with all established CAD/CAM solutions

3D-CAD/CAM Software

With DIN/ISO standard interfaces and an APT (CL-Print) interface, each DATRON machine is compatible to all standard 3D CAD/CAM programs. As standard DATRON use SolidWorks and as an integrated CAM module SolidCAM.

Our customers e.g. use the following programs:

- AutoCAD

- SolidCAM

- IBM: CATIA

- Pro-Engineer

- MasterCAM

- PEPS

- Surfcam

- Edgecam

- u.a.

2D CAD/CAM-Software

The CAD/CAM software package PrimCAM offers excellent features at an affordable price. Its clearly structured menus allow even beginners to write CNC programs in no time at all.

Engraving Software

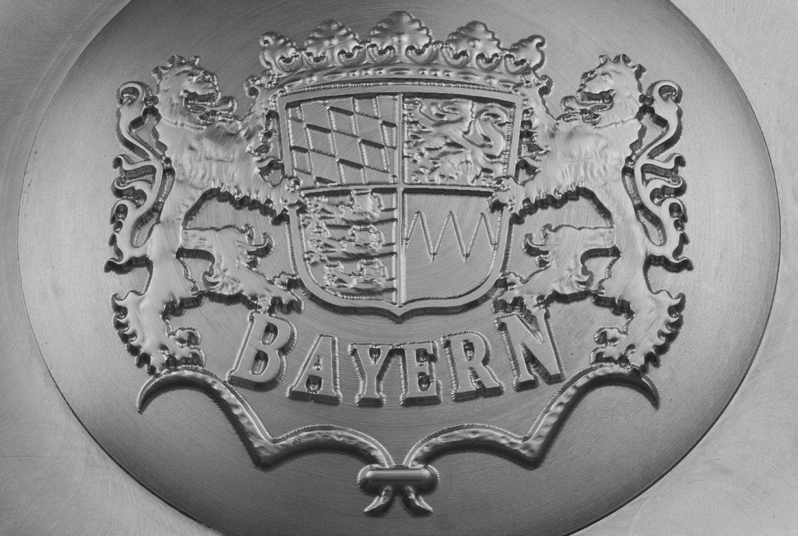

From the simple plate engraving to the creation of complex embossing dies Type 3 fulfils all wishes where artistic or technical applications are concerned. Operating Type3 on a DATRON milling machine you will quickly achieve optimum results.

- PrimeCAM

- MasterCAM

- SolidCAM

- Type3

-

The 2.5D CAD/CAM system PrimCAM implements the philosophy of DATRON machine software consistently for the CAD/CAM area: Easy to learn, easy to operate, but still powerful. The clearly structured menu guidance allows even CAM beginners to create their own CNC programmes within a minimum amount of time. Many special functions of the DATRON CNC control are directly integrated in PrimCAM.

-

Mastercam offers a wide range of complete machining software for 2- to 5-axis milling. Thanks to the modular structure, Mastercam can be tailored to special applications (Mastercam, milling entry, Level1, Level2, Level3). Mastercam is the most frequently used PC-based CAD/CAM software of the world today with more than 85,000 installations.

-

Type3 from Vision Numeric is a specially perfected software solution for 3D CNC machining in the artistic and creative area. 3D engraving, complex dies, coins, jewellery elements and many other — more artistic — applications can be effectively realised and manufactured on the DATRON machine. Further powerful software solutions in this application area are also provided by AHSoft (HCAM) and Delcam (ArtCAM).