"Lubrication instead of Cooling"

By means of concentrated lubrication the friction at the cutting edge is considerably reduced, so that cooling as flood cooling is no longer necessary. Thermally relieved cutting edges result in higher tool life at increased feed rates and reduced cutting speeds.

The atomization of the lubricant into micro-particles causes a much better wetting and distribution of the lubricant when spraying at workpiece surface combined with a strong increase in the lubrication performance. This can be compared with some fog droplets on a window pane which uniformly adhere in contrast to raindrops immediately rolling off after hitting. Even at high pressure on the workpiece the microparticles adhere. Through the press force they extend their surface thus increasing the lubricating effect.

MicroJet Coolant System:

The Microjet coolant system is an upgrade to the existing coolant system. This upgrade replaces the standard venturi coolant configuration with a high pressure mist system. This high pressure mist is best suited in applications where heavy machining occurs or deep channels and pockets are milled. It is also recommended when machining steel. The Microjet system allows for misting various coolant types such as: oil, water-soluble coolants, ethanol etc.

Cooling/Lubrication System DATRON EK-D

The DATRON cooling/lubrication system is for conducting heat away from the milling location. The cooland is sprayed through two Venturi nozzles with compressed air near the milling cutter and comes out as a fine mist on the workpiece and tool.

The heat energy which is generated in the milling process is removed from the milling location by means of the evaporation process. In addition, the coolant lubricates the cutting edge of the tool and increases the tool life.

Thanks to the almost complete evaporation of the coolant, it is not necessary to clean the workpiece after machining.

Properties:

- Can be electronically dispensed via hand-held control unit

- Flexible spray nozzle holder

- Direction-dependent spraying behaviour can be programmed

- Program-controlled spray volume

- Coolant consumption 0 - 1 l/h

Storage tank with filling level monitoring

Robust metal tank for the standard cooling/lubricating system DATRON EK-D. The storage tank with five l capacity is fastened directly to the machine. An automatic filling-level check with a warning message via the control guarantees process safety. A visual filling check is also a component.

Cooling/Lubrication System Microjet ® EK-M

Minimum volume cooling/lubrrication system for DATRON CNC machines

The Microjet® cooling/lubrication system is used everywhere where lubrication is to be done with especially small volumes of liquid, directly, reproducibly and process-safely during milling and engraving.

Adjustable pressure is applied to the cooling lubricant liquid in a pressure tank, which is pressed into capillary hoses which feed into the two-component nozzles. The capillary hose here is for dosing the amount. The desired minimal liquid volume is set via the container pressure, which can be read off a manometer.

The flow speed in the capillaries changes by changing the pressure. This way, the liquid volume can be controlled reliably and evenly up to nearly zero consumption.

Properties:

- Can be switched on and off electronically via the hand-held control unit and control system

- Coolant consumption 0 - 1 l/h

- Various cooling media can be used

Circular spray head 4-nozzle Microjet® EK-VM-R

The spray system consists of a spray head with four nozzles. Their setting angles are designed such that the milling cutter is optimally sprayed. The round spray head is only used with HSK-E 25 spindles and is used in connection

with CleanCut, the rotary-swivel table and machines of type M7 or M10 with an 11fold tool changer.

Application:

- Used with CleanCut, rotary-swivel table and M7 or M10 with 11fold tool changer

Sprayhead 4-nozzle Microjet®

EK-VM-4

The spray system consists of four adjustable nozzles with a bundled jet which are arranged 90° apart around the milling cutter. The spray head can be mounted instead of the EK-VM-2 standard head. With this, the coolant/lubricant is

optimally distributed. The coolant always gets to the tool cutting edge, independent of the milling direction.

Application:

- Used on all spindles with direct shank clamping and DATRON HSK high-frequency spindles

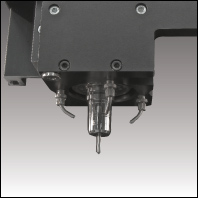

Sprayhead 2-nozzle Microjet®

EK-VM-2

In the case of the 2-nozzle spraying unit, the cooling jet can be optimally adjusted to the machining task with the flexible jointed hoses. This spraying unit is designed for all spindles with direct shank clamping and with HSK collet chucks.

Application:

- Used for all DATRON HF spindles with direct shank clamping and HSK collet chucks