Chip/Dust Disposal

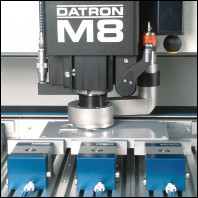

CleanCut CC

With the DATRON CleanCut System, chips can be removed very efficiently. The specially developed suction technique allows you to work in an almost chip-free manner, especially during plate machining. As a result, you save a considerable amount of time since time-consuming cleaning of the machine is not necessary.

Due to non-contact removal of chips, the CleanCut suction head is also suitable for highly sensitive surfaces. The automatic inward and outward movements of the suction head also save a lot of time in practice.

Tool change, tool measurement and 3D measurement can be performed without any restrictions. If the suction funnel disturbs during machining, it can remain fixed in the retracted position or be dismantled. With the optionally available four-nozzle cooling lubrication head, you can remove chips and effectively cool the machining tool at the same time. This combination of suction and minimum quantity cooling leaves almost no residue.

Properties:

- Program-controlled swinging in and out

- Distance to the surface can be precisely set

- Non-contact suction

- Compatible with tool changing station and precision sensor

- Automatic swinging in and out with parking function

- Can be used for spindles with HSK-E 25 taper

- Minimum quantity lubrication is possible

Industrial Vacuum Cleaner RI 331 for CleanCut

The industrial vacuum cleaner RI 331 is particularly suitable for use with the DATRON CleanCut suction system. A large volume preseparator allows the vacuum cleaner to be operated for a long time. The sound-insulated and splash-proof housing is made of painted steel. The vacuum cleaner is also equipped with a pressure manometer for volume flow monitoring.

Pre-separator:

The pre-separator has a collection vessel volume of 160 litres with a tilting undercarriage which can be tilted by a forklift or a crane. The crane eyes and nozzle holders are located on the pre-separator. The pre-separator can be rolled with two steering and fixed rollers.

Graphite Dust Suctioning M7 GSA

The specially powerful graphite dust suctioning system for the milling machine M7 offers the highest possible amount of protection from fine graphite dust for the machine and its surroundings. This is reached by means of a round table suctioning nozzle in the machine‘s protective cover. Thanks to the high suctioning power of the vacuum cleaner, there is turbulence in the nozzle which effectively suctions the generated dust. Special characteristics of the suctioning system include the low noise development and the multi-stage filter system:

- In stage one, course particles are separated from the rest of the dust in the „cyclone“ and are caught in a 50 l tank.

- In stage two, the graphite dust is separated from the suctioned air in the main filter element. The filter element is cleaned by a mechanical device.

DATRON Suction System SAS

The DATRON suction system can be used to dispose of all chips and dust produced during machining.

A brush around the milling tool ensures that the chips and the dust are reached by the suction system.

If the brush is dismantled a 2-nozzle Microjet sprayhead can be mounted.

Chip conveyor M10-NL

The robust and durable design of the DATRON chip conveyor, made of anodised Aluminium extrusions, allows dry and slightly moist chips to be transported out of the machine.

Security Suction System Alto Type 22

Security Suction System (complete with accessories) for the removal of dangerous dust (class M).